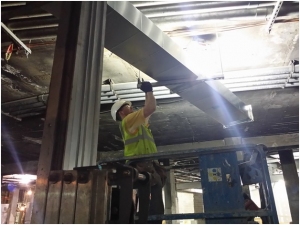

Although it sometimes makes sense to fit rectangular HVAC ducts – in rectangular voids, for example – ducts with curved profiles are more efficient in numerous ways. To name a few: the air meets less resistance, flows more smoothly and exchanges less heat through the walls.

Today most cylindrical ducts are made from spirally wound sheet metal. The spiral winding increases its strength to weight ratio so that it can be produced in lighter or longer sections at a lower cost. It is important to calculate the diameter of the pipe you need to get the required throughput.

The connections between runs of spiral duct are designed to be as simple as possible and provide rapid leak-proof seals. Its thin walls make it easy to miter on-site when necessary.

Although it can be manufactured to order, spiral duct is available off the shelf in a wide range of standard dimensions, along with all necessary fittings like offsets, tees, reducers, saddles, and caps.

Circular cross-sections in galvanized steel are easily the most popular, but several other varieties exist.

Other Materials

Stainless steel (usually 304 or 316) is the most common alternative to galvanized. Aluminum is less common but of course light in weight.

Extra corrosion resistance is available from PVC-coated steel. Antimicrobial and fungicidal coatings are also available.

We have also heard of hot-rolled black steel ducting intended for lagging (due to its inferior finish), and spiral ducting fabricated from wire and plastic composites.

Seams

Galvanized steel ducts formed by tack-welding are leak-proof, but full welding is standard on stainless steel and aluminum. PVC-coated steel cannot be welded without damaging the coating, so it is always fastened mechanically.

Connection Methods

One of the biggest advantages of standard spiral ducts is that they slip together rapidly by means of a multi-lipped rubber gasket. However, you can also join sections using barrel clamps or other fasteners if your application imposes additional performance requirements.

Flat Oval Ducting

When the duct needs to run through a narrower void, a flattened oval profile retains nearly all the benefits of a circular one.

Double Walled Ducting

The usual purpose of a double wall is to contain soundproofing or insulating materials like fiberglass or mineral wool. Insulation can also be applied to single wall ducts as an internal or external liner.